| Symbol |

Description |

Units |

| AC |

Heating coil surface area |

m2 |

| ACmax |

Maximum surface area of coil |

m2 |

| Ain |

Surface area over which heat is transferred in |

m2 |

| Aout |

Surface area over which heat is transferred out |

m2 |

| AP |

Phase change material surface area |

m2 |

| AR |

Aspect ratio |

-- |

| ARmax |

Maximum aspect ratio |

-- |

| ARmin |

Minimum aspect ratio |

-- |

| C |

Specific heat capacity |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CL |

Specific heat capacity of a liquid |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CS |

Specific heat capacity of a solid |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CV |

Specific heat capacity of a vapour |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CPL |

Specific heat capacity of PCM as a liquid |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CPS |

Specific heat capacity of PCM as a solid |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| Ctol |

Relative tolerance for conservation of energy |

-- |

| CW |

Specific heat capacity of water |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CWmax |

Maximum specific heat capacity of water |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CWmin |

Minimum specific heat capacity of water |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CPLmax |

Maximum specific heat capacity of PCM as a liquid |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CPLmin |

Minimum specific heat capacity of PCM as a liquid |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CPSmax |

Maximum specific heat capacity of PCM as a solid |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| CPSmin |

Minimum specific heat capacity of PCM as a solid |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| D |

Diameter of tank |

m |

| E |

Sensible heat |

J |

| EP |

Change in heat energy in the PCM |

J |

| EW |

Change in heat energy in the water |

J |

| EPmeltinit |

Change in heat energy in the PCM at the instant when melting begins

|

J |

| g |

Volumetric heat generation per unit volume |

\(\frac{\text{W}}{\text{m}^{3}}\) |

| Hf |

Specific latent heat of fusion |

\(\frac{\text{J}}{\text{kg}}\) |

| Hfmax |

Maximum specific latent heat of fusion |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| Hfmin |

Minimum specific latent heat of fusion |

\(\frac{\text{J}}{\text{kg}{}^{\circ}\text{C}}\) |

| h |

Convective heat transfer coefficient |

\(\frac{\text{W}}{\text{m}^{2}{}^{\circ}\text{C}}\)

|

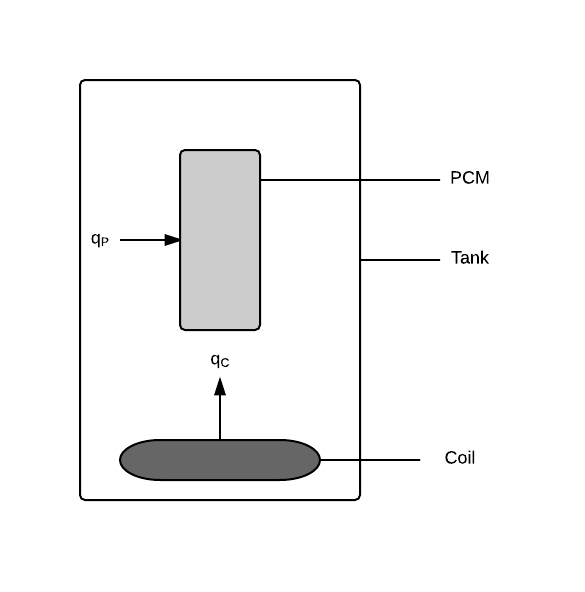

| hC |

Convective heat transfer coefficient between coil and water

|

\(\frac{\text{W}}{\text{m}^{2}{}^{\circ}\text{C}}\)

|

| hCmax |

Maximum convective heat transfer coefficient between coil and water

|

\(\frac{\text{W}}{\text{m}^{2}{}^{\circ}\text{C}}\)

|

| hCmin |

Minimum convective heat transfer coefficient between coil and water

|

\(\frac{\text{W}}{\text{m}^{2}{}^{\circ}\text{C}}\)

|

| hmin |

Minimum thickness of a sheet of PCM |

m |

| hP |

Convective heat transfer coefficient between PCM and water |

\(\frac{\text{W}}{\text{m}^{2}{}^{\circ}\text{C}}\)

|

| hPmax |

Maximum convective heat transfer coefficient between PCM and water

|

\(\frac{\text{W}}{\text{m}^{2}{}^{\circ}\text{C}}\)

|

| hPmin |

Minimum convective heat transfer coefficient between PCM and water

|

\(\frac{\text{W}}{\text{m}^{2}{}^{\circ}\text{C}}\)

|

| L |

Length of tank |

m |

| Lmax |

Maximum length of tank |

m |

| Lmin |

Minimum length of tank |

m |

| m |

Mass |

kg |

| mP |

Mass of phase change material |

kg |

| mW |

Mass of water |

kg |

| MINFRACT |

Minimum fraction of the tank volume taken up by the PCM |

-- |

| n̂ |

Unit outward normal vector for a surface |

-- |

| Q |

Latent heat |

J |

| QP |

Latent heat energy added to PCM |

J |

| q |

Heat flux |

\(\frac{\text{W}}{\text{m}^{2}}\) |

| qC |

Heat flux into the water from the coil |

\(\frac{\text{W}}{\text{m}^{2}}\) |

| qin |

Heat flux input |

\(\frac{\text{W}}{\text{m}^{2}}\) |

| qout |

Heat flux output |

\(\frac{\text{W}}{\text{m}^{2}}\) |

| qP |

Heat flux into the PCM from water |

\(\frac{\text{W}}{\text{m}^{2}}\) |

| q |

Thermal flux vector |

\(\frac{\text{W}}{\text{m}^{2}}\) |

| S |

Surface |

m2 |

| T |

Temperature |

°C |

| ΔT |

Change in temperature |

°C |

| Tboil |

Boiling point temperature |

°C |

| TC |

Temperature of the heating coil |

°C |

| Tenv |

Temperature of the environment |

°C |

| Tinit |

Initial temperature |

°C |

| Tmelt |

Melting point temperature |

°C |

| TmeltP |

Melting point temperature for PCM |

°C |

| TP |

Temperature of the phase change material |

°C |

| TW |

Temperature of the water |

°C |

| t |

Time |

s |

| tfinal |

Final time |

s |

| tfinalmax |

Maximum final time |

s |

| tmeltfinal |

Time at which melting of PCM ends |

s |

| tmeltinit |

Time at which melting of PCM begins |

s |

| tstep |

Time step for simulation |

s |

| V |

Volume |

m3 |

| VP |

Volume of PCM |

m3 |

| Vtank |

Volume of the cylindrical tank |

m3 |

| VW |

Volume of water |

m3 |

| η |

ODE parameter related to decay rate |

-- |

| π |

Ratio of circumference to diameter for any circle |

-- |

| ρ |

Density |

\(\frac{\text{kg}}{\text{m}^{3}}\) |

| ρP |

Density of PCM |

\(\frac{\text{kg}}{\text{m}^{3}}\) |

| ρPmax |

Maximum density of PCM |

\(\frac{\text{kg}}{\text{m}^{3}}\) |

| ρPmin |

Minimum density of PCM |

\(\frac{\text{kg}}{\text{m}^{3}}\) |

| ρW |

Density of water |

\(\frac{\text{kg}}{\text{m}^{3}}\) |

| ρWmax |

Maximum density of water |

\(\frac{\text{kg}}{\text{m}^{3}}\) |

| ρWmin |

Minimum density of water |

\(\frac{\text{kg}}{\text{m}^{3}}\) |

| τ |

Dummy variable for integration over time |

s |

| τPL |

ODE parameter for liquid PCM |

s |

| τPS |

ODE parameter for solid PCM |

s |

| τW |

ODE parameter for water related to decay time |

s |

| ϕ |

Melt fraction |

-- |

| ∇ |

Gradient |

-- |