General System Description

This section provides general information about the system. It identifies the interfaces between the system and its environment, describes the user characteristics, and lists the system constraints.

System Context

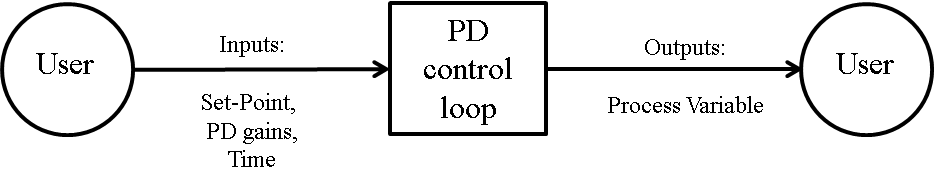

Fig:systemContextDiag shows the system context. The circle represents an external entity outside the software, the user in this case. The rectangle represents the software system itself, PD Controller in this case. Arrows are used to show the data flow between the system and its environment.

PD Controller is self-contained. The only external interaction is with the user. The responsibilities of the user and the system are as follows:

-

User Responsibilities

- Feed inputs to the model

- Review the response of the Power Plant

- Tune the controller gains

-

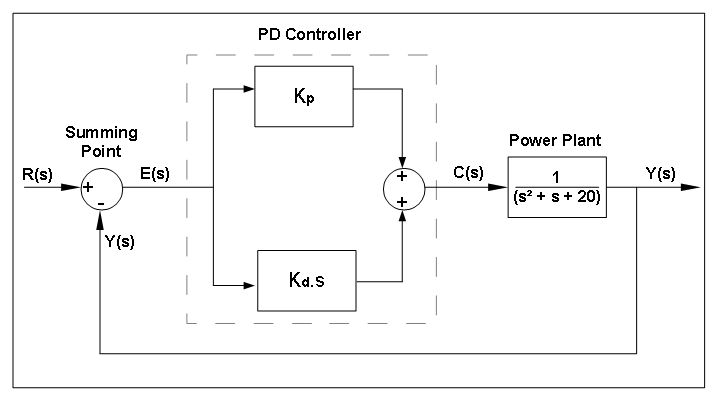

PD Controller Responsibilities

- Check the validity of the inputs

- Calculate the outputs of the PD Controller and Power Plant

User Characteristics

The end-user of PD Controller is expected to have taken a course on Control Systems at an undergraduate level.

System Constraints

There are no system constraints.